Company Profile

Rayhoo Hobo Stamping Factory

2021.12

Established

Wuhu, Anhui

Company address

100 million RMB

Registered capital

55000 square meters

Factory area

190 people

Number of employees

Aluminum alloy

High pressure casting parts

Main business

Product Positioning

Multiple production lines impact high-end

Mechanical press connection

hree, four process large structural parts

Multi-station production line

Small and medium structural parts, chassis parts

nline die production line

Uncoiled blank, progressive die

Small punch connection

Steel plate modules attached to the assembly

Main business products and customer positioning

Multiple production lines impact high-end

Automobile chassis stamping parts

Wuhu Daao, external customers

Auto body stamping parts

Chengfei Rayhoo, external customers

New energy aluminum plate structural parts

New energy customers

New energy vehicle battery box

New energy customers

Smart Factory Planning Solution

High integration of technology and factory

Smart Factory Vision

The future intelligent factory is a human-machine network built by applying industrial network and taking MES system as the core to realize automatic aggregation, analysis and release of dynamic big data information in workshop, assisting scientific and rapid production management and decision-making, and gradually transition to "unmanned factory" .

Smart Factory Vision

The future intelligent factory is a human-machine network built by applying industrial network and taking MES system as the core to realize automatic aggregation, analysis and release of dynamic big data information in workshop, assisting scientific and rapid production management and decision-making, and gradually transition to "unmanned factory" .

Smart Factory Vision

The future intelligent factory is a human-machine network built by applying industrial network and taking MES system as the core to realize automatic aggregation, analysis and release of dynamic big data information in workshop, assisting scientific and rapid production management and decision-making, and gradually transition to "unmanned factory" .

Smart Factory Planning Solution

High integration of technology and factory

Smart Factory Vision

The future intelligent factory is a human-machine network built by applying industrial network and taking MES system as the core to realize automatic aggregation, analysis and release of dynamic big data information in workshop, assisting scientific and rapid production management and decision-making, and gradually transition to "unmanned factory" .

Smart Factory Vision

The future intelligent factory is a human-machine network built by applying industrial network and taking MES system as the core to realize automatic aggregation, analysis and release of dynamic big data information in workshop, assisting scientific and rapid production management and decision-making, and gradually transition to "unmanned factory" .

Smart Factory Vision

The future intelligent factory is a human-machine network built by applying industrial network and taking MES system as the core to realize automatic aggregation, analysis and release of dynamic big data information in workshop, assisting scientific and rapid production management and decision-making, and gradually transition to "unmanned factory" .

Uncoiled blanking stacking line

Technical Features

Uncoiling and blanking equipment: uncoiler, leveler, feeder, blanking press, stacker

Production line function: It can realize two functions of swing shearing and blanking, the number of press strokes can achieve 15~70SPM, and the leveling and outlet speed can achieve 90m/min

Stacking function: stack the sheets cut by the press

Automatic expansion: it can realize the docking transportation of stacks and AGVs

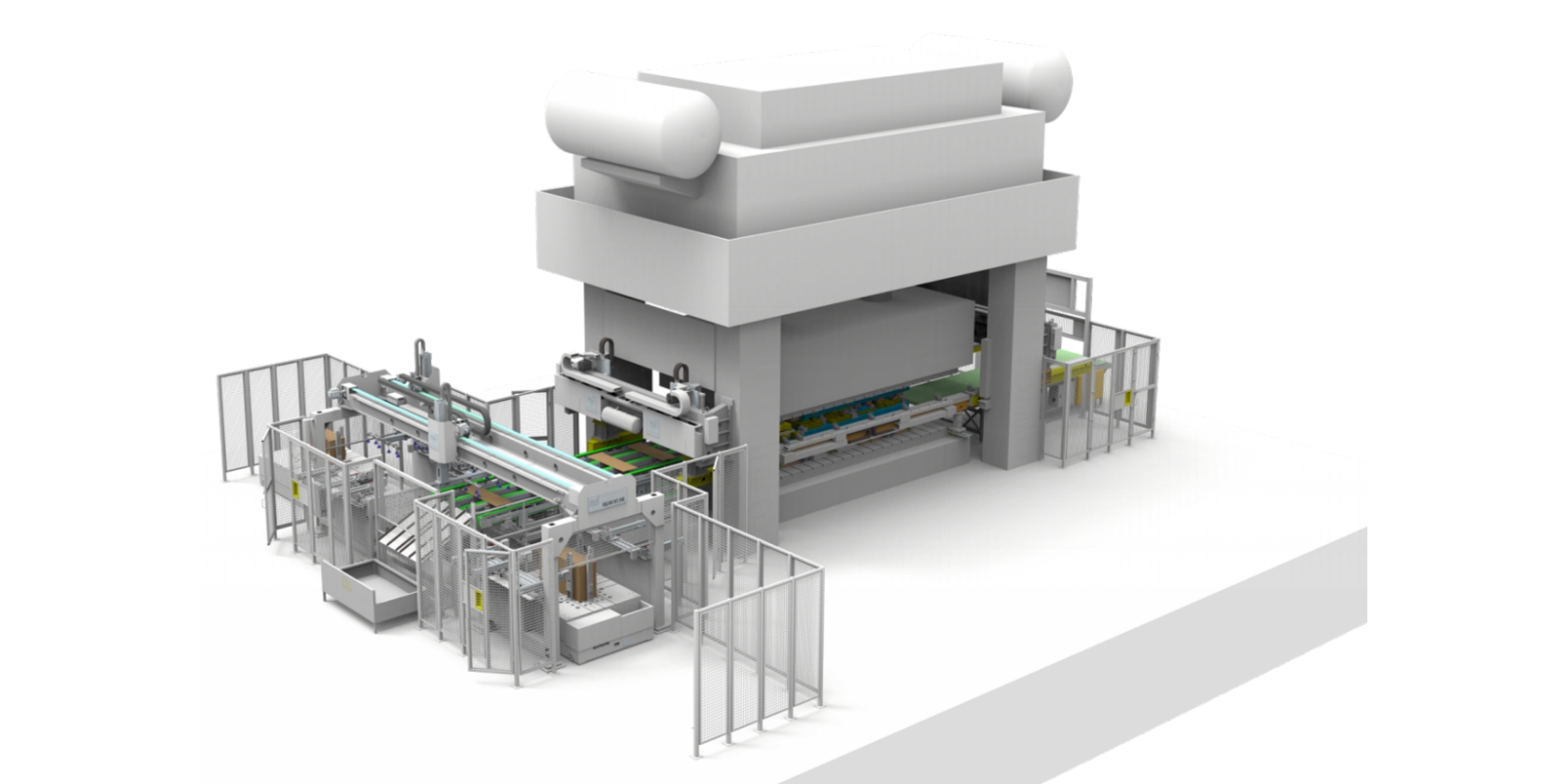

Three-dimensional multi-station production line

Technical Features

Three-dimensional multi-station stamping line equipment: depalletizer, press stamping, finished product conveying

Production line function: It can realize the production of steel and aluminum materials, and the number of press strokes can achieve 12~25SPM

Depalletizing function: can actually produce A/B double pieces

Automatic expansion: automatic visual inspection and automatic palletizing of stamped products can be realized

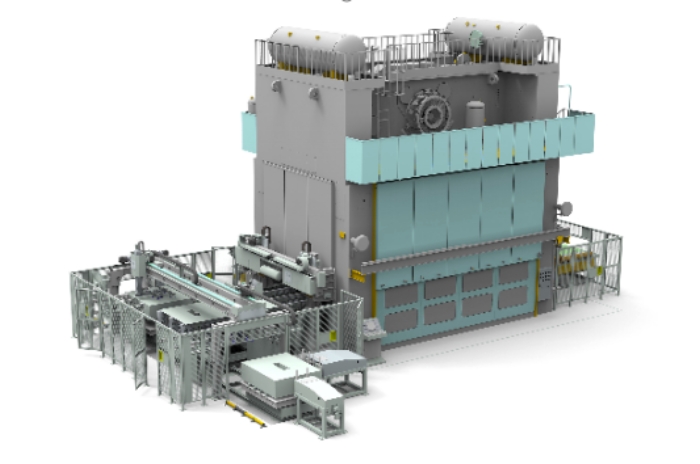

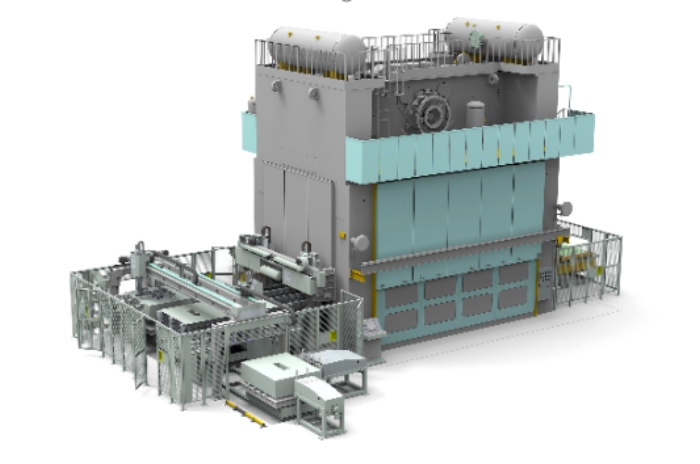

Three-in-one + three-dimensional composite multi-station production line

Technical Features

Three-dimensional multi-station stamping line equipment: three-in-one feeder, depalletizer, press stamping, finished product conveying

Production line function: It can realize the production of steel and aluminum materials, and the number of press strokes can achieve 12~25SPM

Depalletizing function: can actually produce A/B double pieces

Automatic expansion: automatic visual inspection and automatic palletizing of stamped products can be realized

Uncoiled progressive die production line

Technical Features

Uncoiled progressive die stamping line: three-in-one feeder feeding, stamping, finished product output

Production line function: It can realize the production of steel and aluminum materials, and the number of press strokes can achieve 12~25SPM

Depalletizing function: can actually produce A/B double pieces

Automatic expansion: automatic visual inspection and automatic palletizing of stamped products can be realized

Single machine small punch production line

Technical Features

Single-machine small punch connection: destacking mechanism, 6-axis robot, stamping, finished product packing

Production line function: It can realize the production of steel and aluminum materials, and the number of press strokes can achieve 12~25SPM

Depalletizing function: can actually produce A/B double pieces

Automatic expansion: automatic visual inspection and automatic palletizing of stamped products can be realized

Three-dimensional intelligent storage center for stamping parts

Technical Features

High cost performance, strong practicability and wide applicability. Use printed barcodes to match assets instead of manual accounting or unmanned management

Production line function: It can realize the production of steel and aluminum materials, and the number of press strokes can achieve 12~25SPM

Depalletizing function: can actually produce A/B double pieces

Automatic expansion: automatic visual inspection and automatic palletizing of stamped products can be realized

EN

EN CN

CN